Unlock the Secrets to Increased Productivity with Redzone's Newly Released Benchmark Report! Download Today

Welcome to Factory Miracles — the digital magazine from Redzone that honors the frontline connected workers in the Redzone Community! This magazine features stories of achievements and accomplishments from across the Community and around the world.

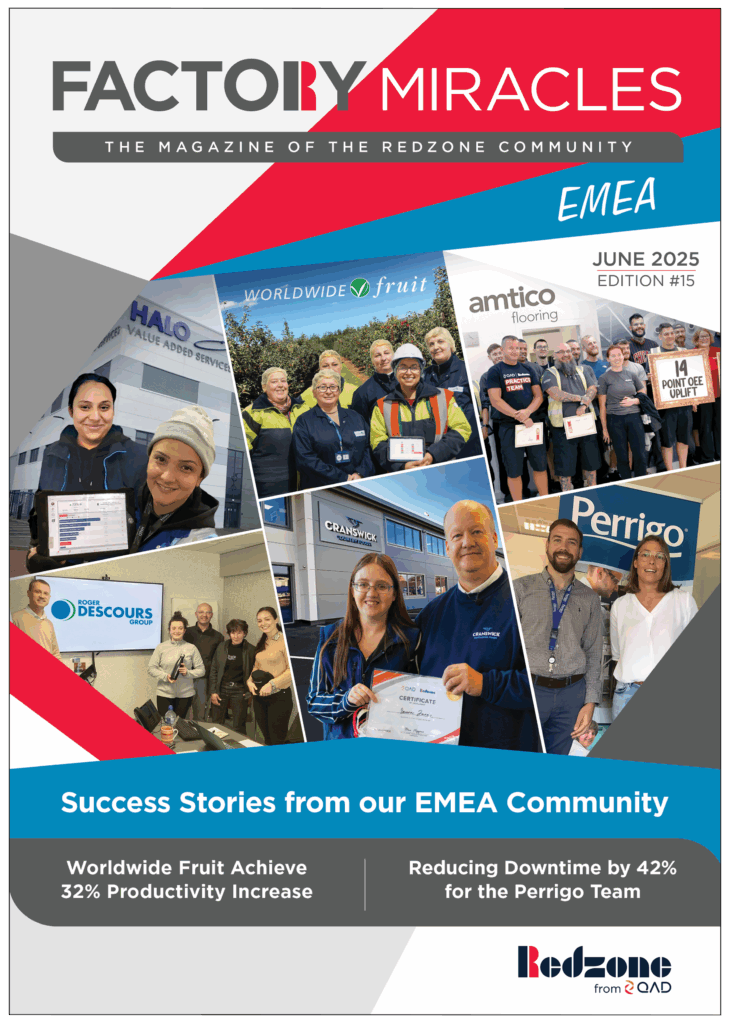

In this first-ever EMEA (Europe, Middle East, Africa/Asia) edition, we celebrate some of the incredible achievements within our EMEA community. This issue presents a collection of stories that showcase the remarkable determination and creativity of your frontline teams and individuals. Those who go above and beyond in their efforts to make a positive impact on a daily basis, and those who demonstrate a dedication and service that is truly inspiring.

In this special 10th Anniversary Awards edition we celebrate all the magnificent winners on the night and congratulate Dot’s Pretzels, Lenexa, for winning the crown jewel of awards – Plant of the Year 2024 – the ultimate recognition of excellence. The Dot’s Pretzels team didn’t just achieve initial success – they elevated it, built upon it, and transformed it into something amazing. Through multiple deployments, they’ve ignited a spark of cross-functional collaboration that lights up their entire frontline and, ultimately, their entire factory.

Our feature story this edition comes from Continuum Packing Solutions, who have not only improved productivity by 23%, but also boosted OEE by 11%, and are creating a culture of continuous improvement that fuels business growth and employee and customer satisfaction!

In conjunction with International Women’s Day, March 8th, we wanted to bring you a special edition of Factory Miracles highlighting just some of the remarkable women we come across daily in our manufacturing lives. This special ‘Women in Manufacturing’ edition celebrates the vital role women play in our industry and the invaluable contributions they make.

2023 ‘Plant of the Year’ winners Taffy Town deployed Redzone back in October 2021, unwilling to miss out on growing business demand. As a result, they not only reduced excessive lead times and reduced overtime to 0%, they improved employee retention resulting in being able to offer a four-day work week.

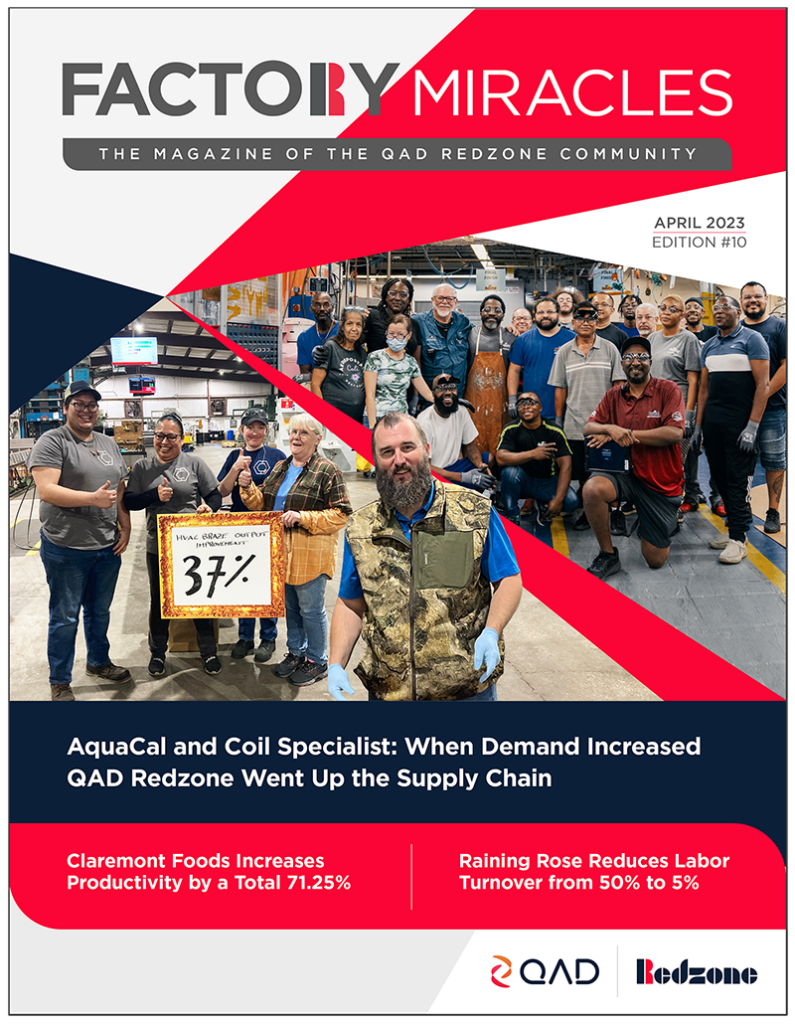

This issue shows how QAD Redzone helped both vendor and supplier keep up with an increase in demand. When AquaCal, a manufacturer of pool heat pumps, had a huge increase in demand during the pandemic, their suppliers Coil Specialist, a manufacturer of fin coils, too felt the pressure to keep up with demand and asked AquaCal just how they were producing so much more? The answer that came back was QAD Redzone…

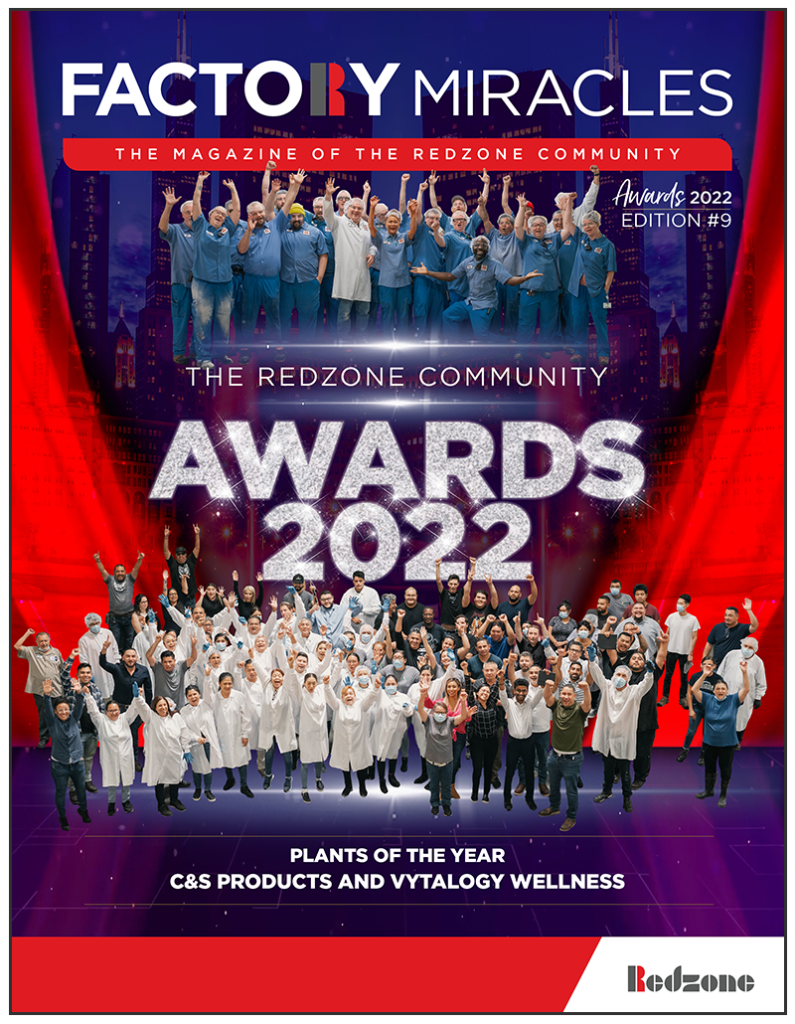

In the last 12 months, Plant of the Year 2022 winner, Vytalogy Wellness has seen outstanding success using Redzone’s connected workforce solution by fully transforming its productivity levels to help reduce the overall pressures of economic downturns. In less than 16 months, Vytalogy Wellness rolled out all four of Redzone’s modules: Productivity, Compliance, Reliability, and Learning. By simply adopting these modules, Vytalogy has seen great success on the frontline, especially when it comes to company culture.

Dot’s Pretzels’ seasoning blend may be top secret, but when you step into any of their four facilities, shop floor employees aren’t keeping their Redzone productivity successes a secret. Behind each pretzel twist – whether it’s the honey mustard seasoned, southwest seasoned, or their original flavor – Dot’s has a wonderfully committed team who have recently transformed from a family-owned business into a Hershey-owned company.