Press Release: QAD Redzone is Front Runner in LNS Research Connected Frontline Workforce Applications Solution Selection Matrix Read Now

We understand that managing the unforeseeable is hard. Stuff happens. But when operators, quality control, and maintenance work together, the negative impacts can be reduced and overall preventive care can lead to “well-oiled” machines and more predictable outcomes.

Significantly reduce unplanned downtime by engaging operators in maintaining their equipment to detect issues earlier and free up the Maintenance team to focus on preventative maintenance.

With Total Productive Maintenance (TPM) in a box, transfer equipment care to operators and remove the tension between production and maintenance – there’s even a “bat-phone” for when things do go wrong.

The Redzone Reliability module expands the Redzone Connected Workforce Solution into your Maintenance department to further extend the value of continuous productivity improvement.

By delivering maintenance specific tools to better manage regular maintenance work orders, the Maintenance team can spend more time on preventative maintenance (PM), but when combined with a new level of connection with production, the whole is greater than the sum of its parts; with operators performing basic maintenance tasks.

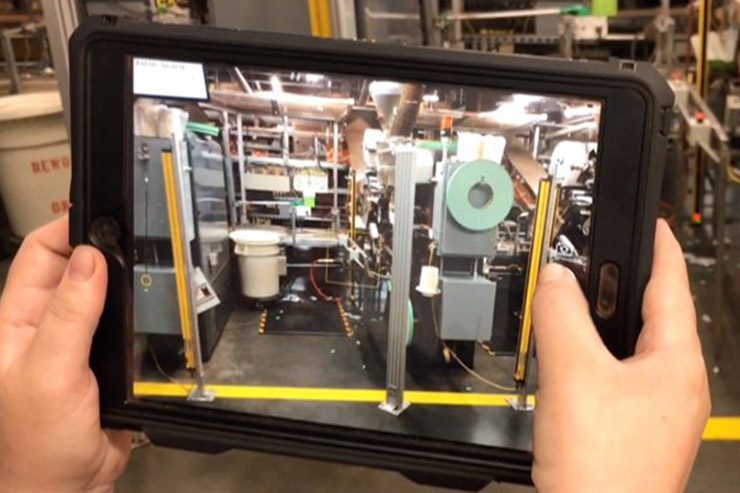

The Redzone Reliability module expands your team’s reach by turning on operators’ sense of sight, sound, and smell to identify potential issues before they result in disruptive downtime. When the inevitable unplanned event occurs, instant communication minimizes its impact.

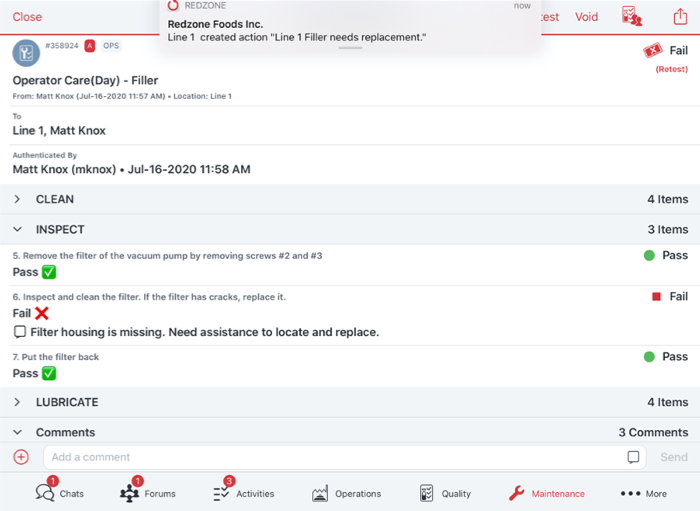

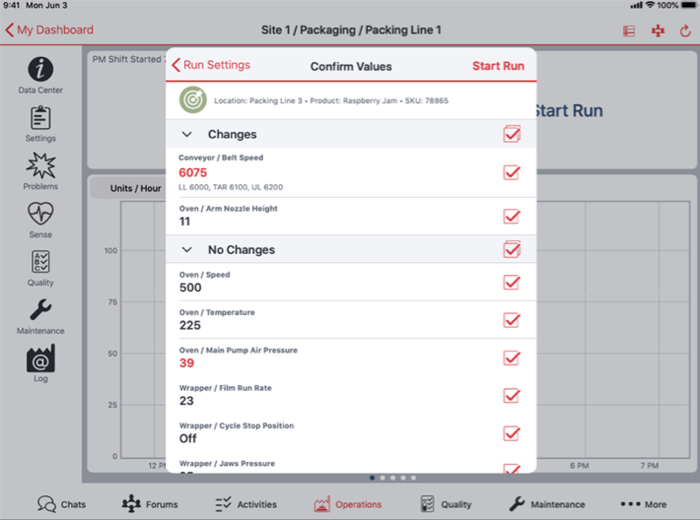

Equipment care is no longer just a maintenance responsibility. With Redzone, factories transfer clean, inspect, and lubricate (CIL) tasks to operators – Ultimately, upskilling operators, freeing up maintenance techs, and preventing unplanned downtime. Digital centerlines ensure one right way to setup and operate the line.

Expand your maintenance resources by including operators on the team.

Remove the barrier between production and maintenance with equipment health reports. The health report allows production and maintenance to dig deeper on key reliability items including early defect detection (operator senses), service requests, breakdowns, CILs, and PMs. The interactions promote upskilling of production employees in the care of their equipment.

While prevention is key, the unplanned inevitably happens. Operators call technicians using ‘Uber for maintenance’ to ensure the right information gets to the right person immediately to minimize downtime. For the first time, plants know exactly when a line stopped, when help was requested, when help arrived, and when the line got back up and running.

Breakdowns happen. Reduce their impact.

The Reliability module completes the connection between the team-of-teams of Production, Quality and Maintenance, to minimize unplanned disruptions and downtime on the shop floor. With everyone working from the same connected workforce solution, the collaboration of the entire Operations team is elevated, and more issues are identified and corrected earlier and proactively because everyone is focused on the same goals.

Typical Outcomes:

Implemented at over 1000 factories around the world, the impact on people, teams, and your business, is transformative. Your people learn by doing; so even the most techno-shy individuals will be experts in no time.

Contact us and let's begin empowering your frontline and growing your bottomline.