Unlock the Secrets to Increased Productivity with Redzone's Newly Released Benchmark Report! Download Today

Quality management software (QMS software) is a formalized digital system that helps manufacturers document, track, and improve their quality processes. It ensures compliance with industry standards, reduces human error, and provides a single source of truth across departments.

Designed especially for modern production environments, QMS software for manufacturing allows teams to manage audits, inspections, and product quality in real-time — streamlining operations and supporting consistent compliance.

Dramatically reduce waste and giveaway by transforming your Quality Assurance program with quality management software — shifting from reactive to proactive, resulting in improved food safety and quicker, more impactful audits.

Our quality management software provides plant-wide dashboards that reduce hassle and mistakes. Miss/fail/warn triggers and alerts mean no check is ever overlooked. Bulletproof your data collection by capturing product images and scanning barcodes for automatic pass/fail, reducing waste and rework. Every record is at your fingertips, so audits and customer inquiries take minutes, not days.

With quality management software from Redzone, reduce waste and variability by proactively adjusting processes when out-of-control conditions are predicted. Automatically calculate real-time statistical parameters like control limits, Cp, Cpk, and Cpp to ensure your processes meet customer specifications.

Redzone plants inspect what they expect for safety and compliance. Conduct audits with weighted scoring to ensure adherence to personnel safety, food safety, and internal management systems. Infinitely configurable Redzone checklists allow plants to go paperless with safety inspections, housekeeping, pre-flight checks and every imaginable task.

Modern QMS software for manufacturing goes beyond simple quality checks — it empowers teams with advanced tools that streamline compliance, reduce risk, and improve collaboration across departments. From linking to ERP systems and managing audit trails to enabling real-time corrective actions, today’s quality management software is built for scale, flexibility, and strict regulatory environments.

Redzone’s platform supports advanced quality practices like Statistical Process Control (SPC), Corrective and Preventive Actions (CAPA), and Cost of Quality tracking. Seamlessly integrate with production data, reduce manual documentation, and stay compliant with standards like FDA, ISO 9001, and ISO 27001. Whether you’re managing non-conforming inventory or preparing for an audit, Redzone’s QMS software delivers the tools you need to succeed — now and in the future.

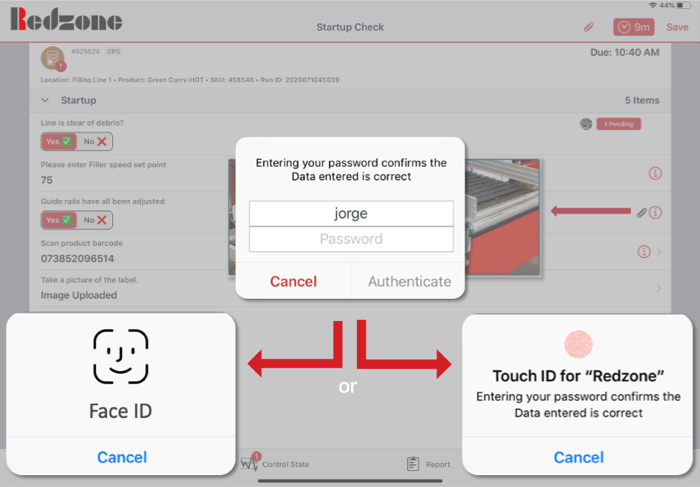

Redzone helps ensure products and services are safe, reliable, and high-quality with secure audit trails, access control, and electronic signature features that meet regulatory requirements.

Provides secure audit trails, access control, and electronic signature features that meet regulatory requirements.

Automates hazard analysis, monitoring logs, and corrective action documentation to support food safety plans.

Tracks procedures, employee training, batch records, and deviations to demonstrate compliance and maintain product quality.

Manages policies, access controls, incident response, and documentation needed for SOC 2 audits.

Maintains compliance checklists, audit histories, and traceability logs to meet BRC requirements.

Manages supplier records, training, risk assessments, and audit documentation for SQF certification.

Enables compliance with recognized schemes by unifying documentation, monitoring, and continuous improvement tools.

There are four widely recognized types of quality management systems: Total Quality Management (TQM), Six Sigma, ISO 9001-based QMS, and Quality Function Deployment (QFD). Each system offers a different approach to ensuring product and process quality. Redzone’s quality management software can complement or support these frameworks by digitizing and streamlining key quality activities.

The most widely implemented QMS globally is ISO 9001, a standardized quality management system focused on consistent quality practices, continual improvement, and customer satisfaction. Redzone’s qms software helps teams meet ISO 9001 standards by automating documentation, quality checks, and audits.

The seven basic tools of quality management include: cause-and-effect diagrams, check sheets, control charts, histograms, Pareto charts, scatter diagrams, and flowcharts. While traditionally used manually, modern qms software for manufacturing can integrate these tools digitally to make data-driven decision-making faster and more accessible.

Contact us and let's begin empowering your frontline and growing your bottomline.