Learn How 1,500+ Factories Achieved Average 26% Productivity Gains in Just 90 Days Download Report

John Ponte

June 24, 2024

Instant connectivity is an accepted reality in the “Flat World” we live in today. The concept of the connected worker is at the forefront of this shift. Technology is the key driver behind this transformation, providing the network and systems that enable real-time communication and information sharing among workers.

The same principles apply to manufacturing plants. Just as technology helps bring people together, it can also unite frontline workers in new ways, giving them the means of communicating with each other, accessing important resources and staying informed from anywhere on the shopfloor.

In this article, we’ll take a closer look at the connected worker technology empowering modern factory teams and driving manufacturing success.

A connected worker platform is a digital solution designed with a singular purpose in mind: to better enable frontline workers to connect, communicate and collaborate. By enhancing workers’ ability to connect with one another and share information in real time, manufacturing plants can optimize operations, drive greater productivity, improve safety conditions and create a positive culture in which workers feel empowered.

Connected worker software can also help manufacturers address common challenges, such as unexpected equipment failures, skills gaps within their existing workforce and quality controls, ultimately giving them the tools and systems they need to adapt to changes within their industry.

The connected worker (as opposed to his “unconnected” counterpart) may be fitted with wearable devices such as smart glasses, smartwatches or helmets powered by the internet of things (IoT), a network of devices and sensors capable of communicating in real time. These wearables enable the connected worker to capture information in the form of voice recordings, photos and videos to share with fellow frontline workers, send and receive real-time updates on various processes and even monitor environmental conditions for safety purposes.

The connected worker may also be equipped with a personal device in the form of a smartphone or tablet, which they can use to view dashboards and other digital displays and communicate with colleagues, supervisors and remote experts from anywhere in the facility. When paired with advanced technologies such as radio-frequency identification (RFID) tags and augmented reality (AR), these devices enable the connected worker to monitor equipment performance, track assets and share what they’re seeing in real time with colleagues.

In addition to having access to the tools they need while on the job, the connected worker also has vast quantities of information at their fingertips, from instructional videos and training courses to digital forums and standard operating procedures. With this information at their disposal, the connected worker has the knowledge, skill and confidence to do their job effectively and achieve sustainable growth within their career.

Now imagine the connected worker, multiplied across your entire workforce. With entire teams’ worth of workers with the confidence and capability that only real-time communication and collaboration can deliver, you’ll begin to see substantial improvements in operational efficiency, productivity, employee engagement and overall job satisfaction.

Manufacturing facilities have traditionally relied on written and verbal communications to share information. While these modes would probably never go away, they lack the immediacy and level of detail required to manage complex manufacturing operations and to set frontline workers up for success. While telephones, two-way radios and corporate email (to which few frontline workers have access) improved communications, these technologies pale in comparison to the capabilities of a connected worker platform.

In a time characterized by constant innovation — both in the workplace and in our day-to-day lives — connected worker technology offers manufacturers a multi-faceted approach to addressing long-standing challenges. Here are just a few of the ways you can benefit from implementing connected worker software in your facility:

Ultimately, connected worker platforms enable manufacturing employees to feel more engaged — in their role, with their peers and with their company’s overall mission and goals. And more engaged workers lead to greater job satisfaction, higher retention rates, better team morale and a positive company culture.

Access Your Free Copy of Our 2022 Frontline Workforce Engagement Study >>

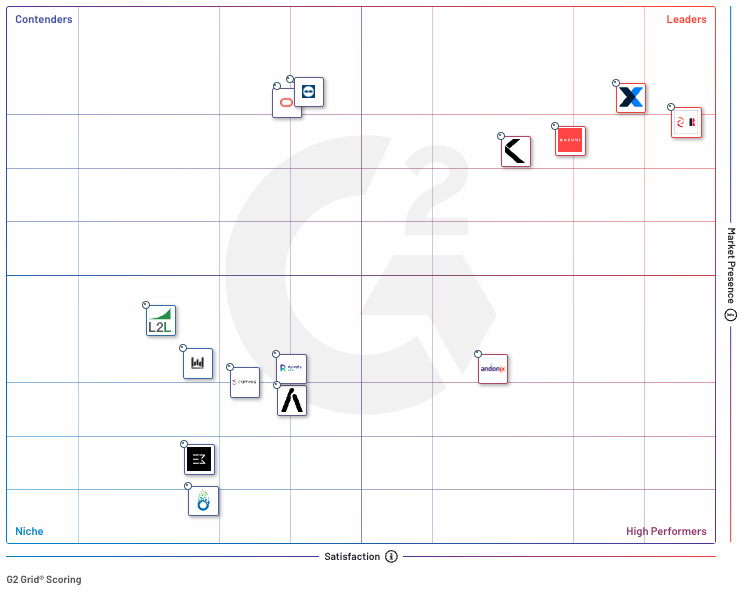

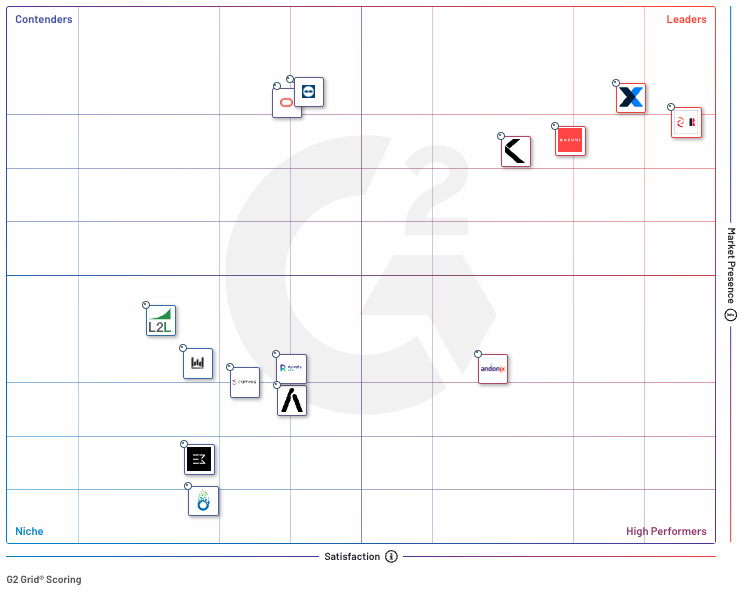

If you’re in the market for a connected worker platform, you’re in luck — there’s certainly no shortage of available systems and solutions from which to choose. But finding the right platform for your facility is sometimes easier said than done, which is why we’ve compiled this list of key criteria to look for to aid you in your search.

When comparing connected workforce solutions, ask yourself:

For over 10 years, QAD Redzone has been committed to helping manufacturers tap into frontline workers’ potential by giving them the tools they need to succeed. Our SaaS-based connected worker platform focuses on five key areas — frontline collaboration, productivity, compliance, reliability and learning — to help streamline manufacturing operations and, most importantly, make workers feel confident, empowered, and connected.

Our software and our signature, worker-first approach has led to countless success stories amongst our clients — but don’t take our word for it. Watch any one of our customer interviews or download a copy of our 2023 Productivity Benchmark to see firsthand how QAD Redzone can help you achieve real results.

John Ponte John is QAD Redzone’s Senior Director of Growth Marketing and brings a background of over 20 years in B2B Software. He is responsible for setting the growth strategy and driving global demand generation strategies to boost pipeline, new customer acquisition, and create expansion opportunities. When John’s not tracking Marketing and business targets, you can find him playing tennis, and even officiating as a national umpire and referee, working with local charities he supports, and enjoying time with family.

Twice the Frontline Engagement: Priceless A spring in the step, a smil...

Contact us and let's begin empowering your frontline and growing your bottomline.