Unlock the Secrets to Increased Productivity with Redzone's Newly Released Benchmark Report! Download Today

Workers today want more than a job — they want to see that their efforts help advance them in their careers. With transparency of skills required to progress within a manufacturing organization, frontline workers are empowered to direct their progression on the shop floor and beyond.

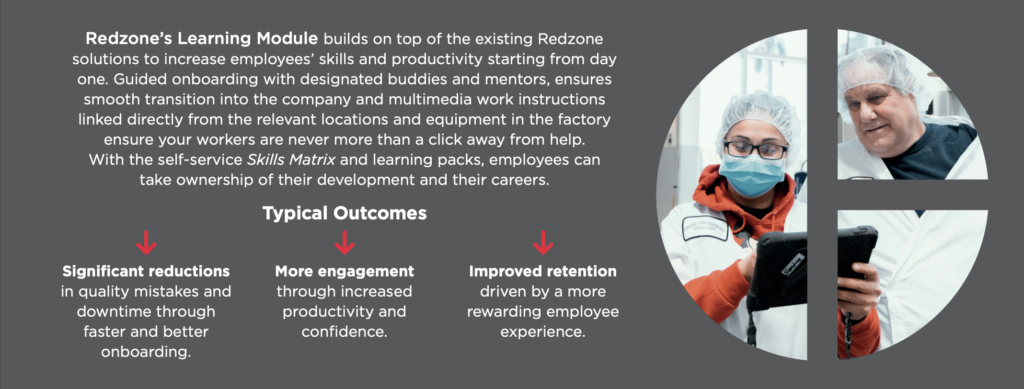

Reduce production losses and employee turnover with a modern LMS for manufacturing—onboard faster, train better, and share knowledge across the factory floor.

New employees feel part of the team on day-one, ramp up faster, and have career progression. Be your town’s destination employer!

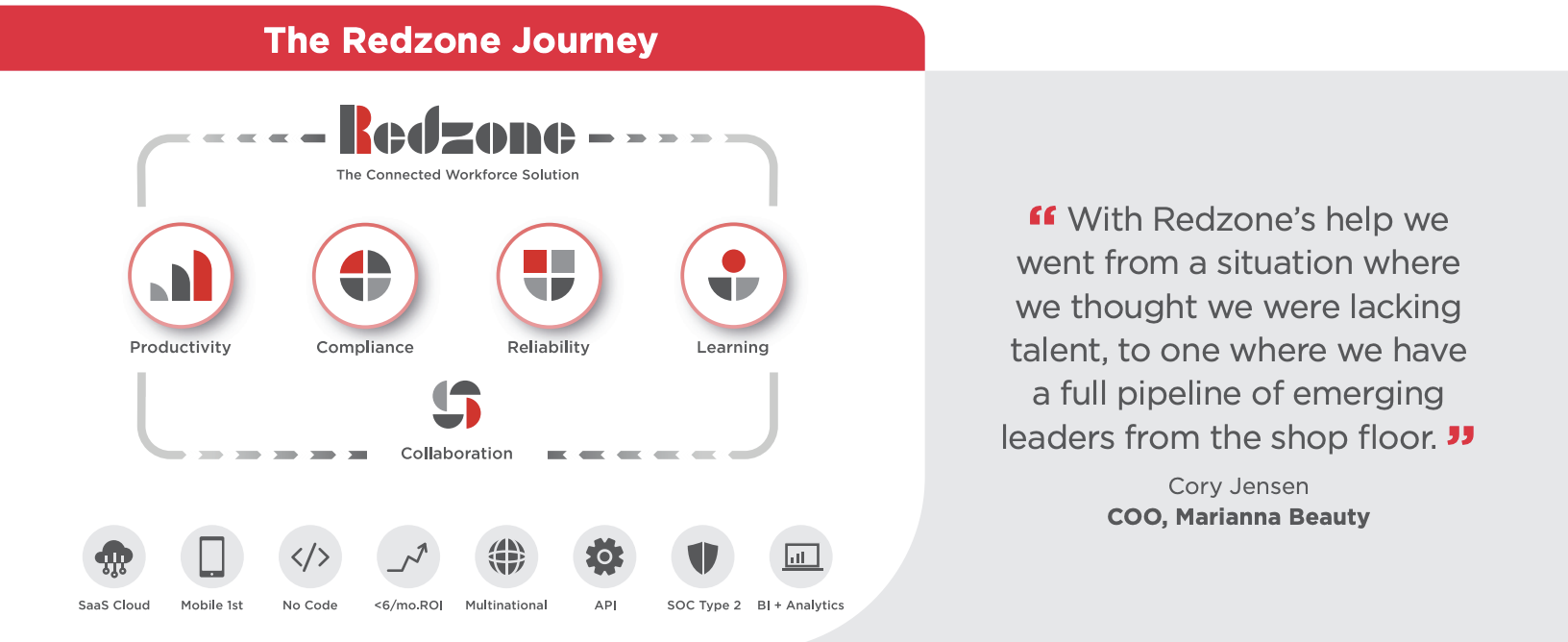

The Redzone Connected Workforce Solution takes frontline productivity to new levels. Its Learning module acts as an LMS for manufacturing, personalizing each employee’s experience to streamline onboarding and improve retention.

Modern training methodologies are cookie-cutter, classroom based and haphazard, with a one-size-fits-all approach focusing more on checking the boxes than developing the skills needed to excel at one’s job.

As a purpose-built LMS for manufacturing, Redzone Learning takes a more engaged approach, putting skills and career development in the hands of each employee. This results in better knowledge retention—in context of their job—through an on-demand, self-service platform that’s tightly aligned with the skills and behaviors coached-in with the Redzone Way.

Day one in a plant can feel daunting. With Redzone, new employees feel part of the team with plant-wide welcome screens and a digital buddy system. Leader welcome videos, learning packs, and knowledge verifications ensure new employees ramp-up fast, feel competent, and decide to stay.

Safety is foundational in any manufacturing environment. Redzone’s LMS for manufacturing enables safety-first onboarding with equipment-specific training videos, plant-wide compliance tracking, and continuous reinforcement of safety procedures.

Pre-seeded content on industry-standard topics like LOTO and PPE allows your plant to be compliant using Redzone’s Learning module quickly. By embedding safety lessons at the point of use, teams stay compliant and reduce incidents from day one.

Redzone is a fully connected workforce solution and leverages the connected platform to improve plantwide safety. Instant in-app communications let teams share unsafe conditions observed. Near-miss and incident reporting are documented with photos, 5-why and root cause analysis applied, and identified follow-up actions are tracked to completion automatically.

Goodbye outdated SOPs in three-ring binders… Hello YouTube for the factory! Nobody reads manuals at home and they don’t want to do it at work. With Redzone, teams control their own production process development.

Don’t make the frontlines search for the answers… have the answers find them!

With this LMS for manufacturing, real-time digital skills matrix, learning packs, and mentors-on-demand allow frontlines to acquire new skills. As this takes hold, your teams become cross-trained and multi-skilled—creating a learning organization. The real-time skills matrix allows leads and supervisors to optimize flexibility to meet production needs.

Redzone’s Skills Matrix allows team leaders and team members to quickly see what skills they’ve achieved and what certifications they’ve completed. The Expiry dashboard highlights who is ready for annual certifications, keeping individual employees and the factory as a whole compliant.

Redzone’s LMS for manufacturing also enables certification tracking, helping supervisors monitor operator qualifications, flag expiring credentials, and plan timely retraining. This functionality strengthens compliance and ensures your workforce is always audit-ready—key expectations in a modern manufacturing learning management system.

Redzone allows the frontlines to own their progression turning jobs-for-now into careers-for-life.

Augment onboarding with continuous learning available throughout the factory.

Redzone Learning is a cloud-based LMS for manufacturing. This gives your team 24/7 access to training without disrupting production or requiring IT-heavy installs. Redzone’s learning management system software is accessible across devices, so employees can learn on the floor, in the classroom, or remotely.

Unlike on-premise platforms, a manufacturing learning management system in the cloud ensures instant updates, centralized control, and consistent training delivery—keeping your workforce aligned, compliant, and productive. With enterprise-level management, it’s easy to ensure each site has the tools they need to maintain compliance with OSHA, GMP, HR, and corporate trainings.

With a structured LMS for manufacturing, 90 days is the perfect amount of time to create meaningful process and behavioral change without overwhelming your organization. The repeatable, predictable program consists of:

The average factory in the Redzone Community is losing around $1.6M annually due to short-staffing and a lack of cross-skilling. The Learning module significantly reduces that loss through increased cross-skilling and a better employee experience.

Blackboard is one of the most widely used learning management system software platforms. While it’s common in education, it’s also adopted in business environments for training. For manufacturers, platforms like Redzone provide purpose-built LMS for manufacturing needs that focus on productivity, safety, and compliance.

A strong LMS for manufacturing maximizes a team’s ability to access, learn, and use content while also providing managers with documentation of this training to track compliance throughout the factory. Tools that best enable these outcomes include mobile access, real-time skills tracking, compliance and safety training, and customizable forms to reflect conditions and procedures within specific factory environments. Redzone’s platform combines all of these features with a user-friendly interface designed specifically for factory teams.

Contact us and let's begin empowering your frontline and growing your bottomline.