Unlock the Secrets to Increased Productivity with Redzone's Newly Released Benchmark Report! Download Today

Customers / Industries / Snacks & Confectionery

Extensive product catalogs, complex manufacturing processes, ever-changing food safety regulations and more — snack and confectionery manufacturers face a long list of challenges when turning raw materials into tasty treats.

But no more: With QAD Redzone’s snack, confectionery and candy management software, plants can carefully plan for every step of the process and discover hidden efficiencies, maintain compliance and transform their company culture along the way.

Boost your competitive standing by significantly increasing your productivity in just 90 days, enabling you to overcome tight margins and become the lowest-cost producer.

More easily manage expensive raw materials with statistical process control (SPC) and out-of-the-box analytics to reduce waste and giveaway for baked goods.

Improve equipment reliability and keep volumes on your long lines high by activating operator care across your facility.

Comply with changing food safety regulations and packaging requirements by digitizing paper-based processes for quicker, more impactful audits.

Ensure the highest quality throughout every step of the manufacturing process with plant-wide quality dashboards and detailed digital records.

Become more action-oriented with action management and kaizen events to eliminate frustrating issues that continuously drain your productivity.

Dramatically shorten changeovers and other planned downtime to reduce spoilage risks for materials that are sensitive to environmental inconsistencies.

Integrate with your ERP system of choice to access real-time production data to optimize production scheduling and ingredient and inventory management.

Trace raw materials and the flow of product throughout your facility to ensure quality and improve allergen segregation and management.

Maintain detailed records of current and new product recipes, including versions, revisions and batch history notes, all in one place.

Minimize IT burden and environmental risks with secure cloud technology and off-the-shelf automation.

Every other year, we conduct a benchmark study against the QAD Redzone 90-day productivity program to assess the effectiveness of the QAD Redzone Connect Workforce Solution. This study compares baseline OEE to the resulting OEE uplift after 90 days and calculates the productivity improvement.

All of QAD Redzone’s community members see OEE uplifts in 90 days — sophisticated, global manufacturers can expect double-digit increases, while smaller, less mature plants see OEE uplifts of >30%.

With an average OEE uplift of 12% and an associated 22% productivity improvement across the entire sample, users enjoy additional capacity without adding resources and can reduce costs without increasing output.

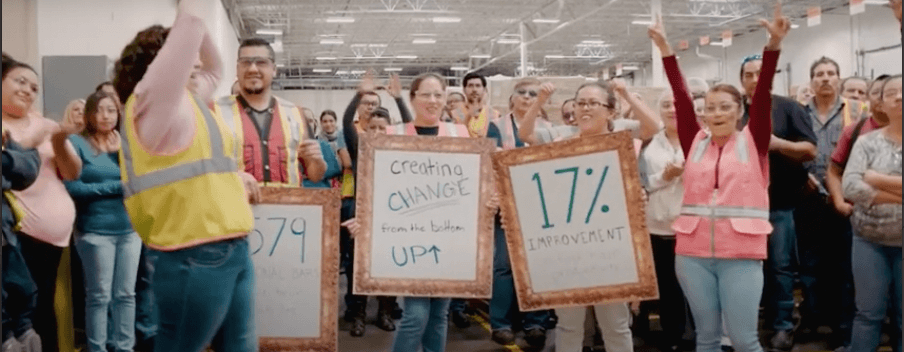

Perhaps the most impactful outcome of this study is the cultural phenomenon that results from improved communication across all plants considered.

See what results manufacturers have achieved using our snack and candy management software:

Our snack and confectionery management software helps manufacturers achieve sustainable and organic double-digit productivity improvements to increase revenue and margins, all without adding people or equipment.

Our solution enables plants to motivate frontline workers through on-the-job learning opportunities and real-time communications, dramatically reducing turnover and transforming a disengaged workforce into a collaborative, connected team that’s energized to excel. With QAD Redzone on your side, you’ll be able to create a lean manufacturing culture that embraces continuous improvement, all driven by shop floor ownership.

We understand that snack and confectionary manufacturing is a complex industry that requires many different software solutions to manage the various aspects of the production process. Our snack and confectionary management software solution features integrations with various systems, including:

By integrating our snack and confectionary management software solutions within these systems, we enable you to streamline operations, reducing waste and downtime, which helps to lower costs and increase revenue.

Discover how plants authentically transformed their level of frontline engagement.

Contact us and let's begin empowering your frontline and growing your bottomline.