June 23, 2023

Manufacturing productivity is the lifeblood of a thriving industrial manufacturing sector, and optimizing processes for streamlined operations has never been more crucial. As businesses face increasing competition, those that invest in maximizing productivity gain a clear advantage.

By utilizing key metrics and equations, you can measure your operational performance and identify areas for improvement. Applying practical strategies can then help to streamline workflows, reduce waste and improve overall efficiency on the shopfloor.

Discover how QAD Redzone’s cutting-edge technology and industry expertise can support your efforts to enhance factory productivity, increase profitability and maintain a competitive edge. Continue reading as we explore the fundamentals of manufacturing productivity to help set your business on the path to sustained success.

At its core, manufacturing productivity is the output produced per unit of input. It measures the rate at which a business transforms raw materials and resources into finished goods sold to consumers. A higher rate of productivity indicates that a company is efficiently utilizing its resources, leading to lower costs and higher profit margins.

There’s a direct correlation between manufacturing productivity and a company’s profitability and competitiveness. By increasing productivity, businesses can:

To accurately assess manufacturing productivity, consider the key inputs involved in the production process. They can be categorized into four main groups:

Manufacturing productivity is crucial for businesses, directly impacting their bottom line and long-term success. Efficiently transforming input into output is vital for companies to stay ahead in an increasingly competitive market. Here, we explore the significance of manufacturing productivity and the various benefits it offers:

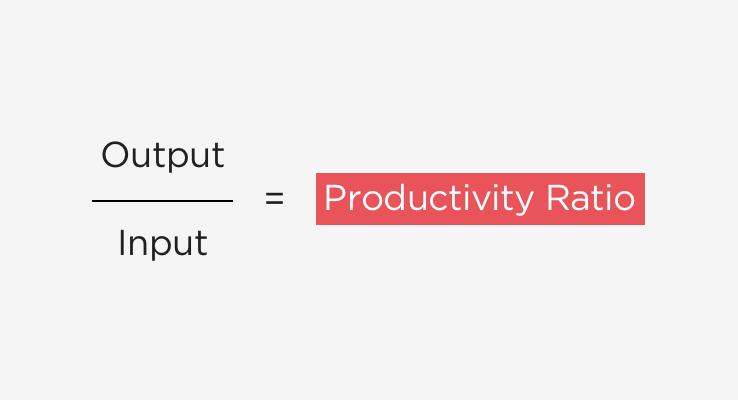

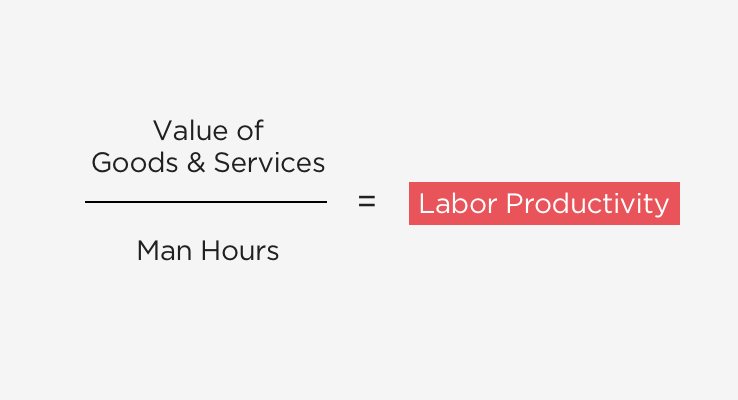

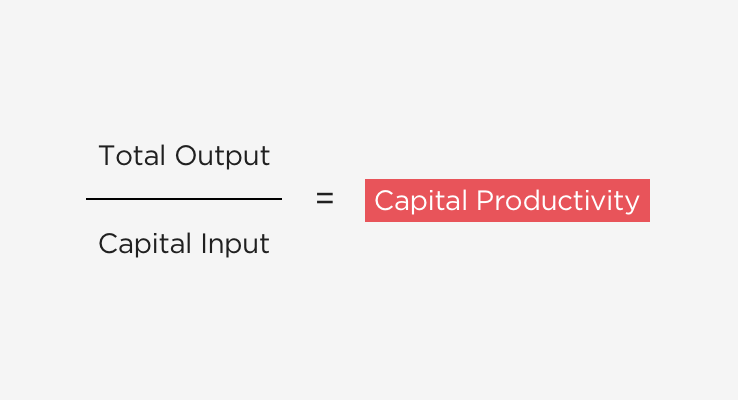

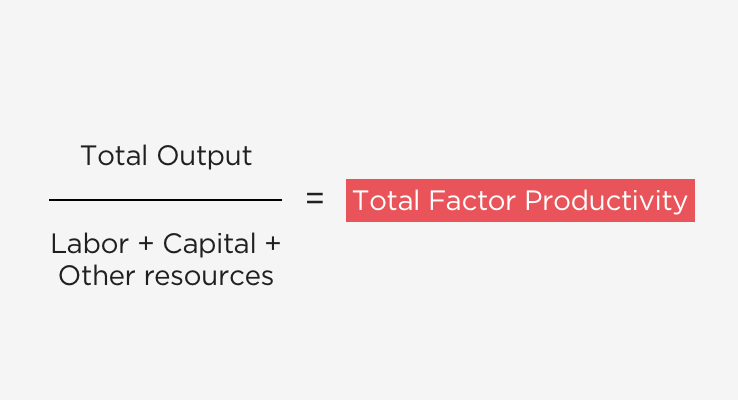

Productivity is calculated by dividing the total output generated by a company by the total input employed in its production process. Various productivity measures can be used depending on the specific input or combination of inputs being assessed.

Calculating manufacturing productivity is not always a straightforward task, and businesses may face various challenges, such as:

Proactively addressing these challenges and choosing the most suitable productivity measures for your business enables you to monitor and optimize your manufacturing processes for continuous improvement and long-term success.

Improving manufacturing productivity is essential for businesses seeking to maintain a competitive edge in the industry. The following actionable tips can help you optimize your production processes and drive efficiency:

QAD Redzone offers innovative solutions designed to assist manufacturing businesses in enhancing their productivity, driving efficiency and achieving lasting success. By combining advanced technology with a deep understanding of the industry, QAD Redzone provides valuable tools and resources to support businesses in their pursuit of optimal manufacturing performance.

Here’s a closer look at some of the key features and benefits of QAD Redzone’s offerings:

Manufacturing productivity plays a critical role in a company’s ability to succeed in today’s competitive environment. QAD Redzone’s comprehensive solutions provide the essential tools and resources to elevate your manufacturing operations, optimize resource utilization and drive growth over the long-term.

Experience the transformative impact of working with QAD Redzone. Begin your journey by assessing your current productivity levels using our Manufacturing Productivity Calculator. Discover how QAD Redzone’s cutting-edge technology and industry expertise can support your efforts to improve manufacturing productivity, increase profitability and maintain a competitive edge.

Twice the Frontline Engagement: Priceless A spring in the step, a smil...

Contact us and let's begin empowering your frontline and growing your bottomline.