Unlock the Secrets to Increased Productivity with Redzone's Newly Released Benchmark Report! Download Today

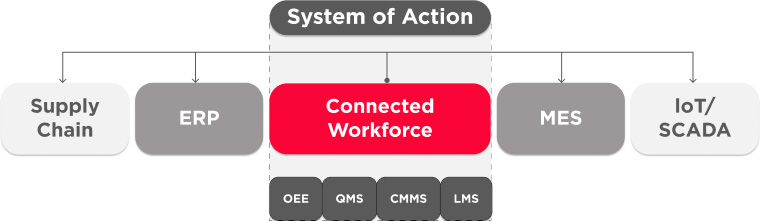

Redzone is the only Connected Workforce Solution that combines intuitive, mobile-first software with hands-on coaching to drive real, measurable transformation on the plant floor.

While other platforms digitize paper or generate dashboards, Redzone goes further—embedding daily performance habits into your frontline teams, unlocking productivity, quality, and engagement gains that actually stick.

Most tools stop at visibility. Redzone delivers outcomes with faster deployment, higher adoption, and lasting results.

Real-time visibility into OEE, downtime, and throughput, on a platform built for frontline awareness, communication, and collaboration. Redzone drives ownership, action, continuous improvement, and frontline engagement by connecting teams to real-time production data. Redzone Productivity defined the CW space – and continues to innovate as competitors rush to copy color schemes and terminology.

Redzone Compliance brings paperless quality checks seamlessly integrated with production. Compliance builds on the Productivity platform, anchoring each check with context, like time, place, and SKU within the production record. Workflows triggered by shopfloor events, automatic alerts, and real-time SPC leverage the CI routines taught by your Redzone coach to drive total quality manufacturing (TQM) and error-proof each process, reducing scrap, rework, and giveaway.

Manage parts inventory, PMs, and work orders – reducing the workload of overburdened maintenance teams with Redzone Reliability. Frontline operators take ownership of their equipment with proactive maintenance tasks like startup checklists and CILs to increase equipment care and reduce breakdowns. When breakdowns do occur, maintenance teams are instantly notified, improving response and repair times.

On-demand training makes Redzone Learning the force multiplier for your factory team. Operators and techs have access to materials in real time and at the point of use, to help them do their jobs better. Learning is a robust LMS with management tools like pre-seeded content, training expiry, skill matrix, and customizable learning packs. Ensure training compliance, reduce ramp-up time, and give frontline teams the power to upskill themselves.

Redzone was built to be different and better. Here’s what truly sets us apart from the other solutions – and why manufacturers trust Redzone to deliver real, lasting results.

All-in-One Platform: Plantwide communication problem-solving begins with Productivity, bringing everyone into the conversation of how to Win the Day. Unify production, quality, maintenance, and learning workflows in a single connected workforce platform.

Dedicated Coaching: 80+ expert coaches help embed daily CI habits and frontline ownership—on-site, in person.

Quick Implementation: Go live in just 6-8 weeks, without burdening IT teams. Redzone’s cloud-based, mobile-first platform accelerates adoption on the frontline so you’re seeing your ROI instead of seeing your timelines slip.

AI that makes frontline teams stronger: Champion AI prompts production, maintenance, and quality teams with real-time, contextual insights. Connected to shopfloor events, Champion AI is the shopfloor’s greatest advocate – providing guidance to prevent problems before they happen and make every run the best run.

Customized Deployments: Each factory’s biggest opportunity is unique – Redzone deployments are aligned with plant strategic initiatives. Redzone Productivity opens the door to CI with plant-wide communication and coaching in habits. Plants decide how those habits are leveraged to support critical initiatives.

Scalable Solution: Enterprise dashboards create instant understanding of performance by site. Centralized administration of specifications, SOPs, and training makes it simple to create standardized material and monitor compliance.

Real-Time Communication and Collaboration: Integrated chat, voice, video, and alerts. Connect your whole team, across roles and shifts, even in other plants across the country or the world, in the moment.

Flexible Integration: Designed to be “IT light” and integration agnostic, Redzone integrates with existing edge devices and IT/OT data sources to make it simple to add to your tech stack.

User-Driven Adoption: making high user reviews all the more significant for a Connected Workforce Solution.

Top-Rated by Real Manufacturers: Redzone is consistently top-ranked on G2, Capterra, and Software Advice for categories like Manufacturing Execution Systems, Quality Management, and Workforce Engagement.

Join the 1,500+ plants already transforming their frontline operations with Redzone. See how Redzone helps teams like yours increase output, boost morale, and build a better culture—from day one. Book your personalized demo today by filling out the form.

Redzone is the only Connected Workforce Solution with real performance data across 1,500 factories that have been measured over the last 10 years of production history. This comprehensive report demonstrates Redzone’s proven ability to transform factory operations and foster a culture of continuous improvement, delivering significant financial impact and sustained growth.

In the first 90 days of implementing Redzone, our customers see an average increase of:

Contact us and let's begin empowering your frontline and growing your bottomline.