Press Release: QAD Redzone is Front Runner in LNS Research Connected Frontline Workforce Applications Solution Selection Matrix Read Now

March 25, 2024

In the realm of lean manufacturing, where efficiency and waste reduction are paramount, tools like the Andon system have become indispensable. Andon systems are visual signaling methods designed to streamline communication, enable quick problem identification, and foster continuous improvement on the production floor.

Today, as industries strive for heightened efficiency and agility, the role of Andon systems has only grown in importance. In this article, we delve into the essence of Andon systems, their working principles, benefits, and how innovative solutions like Redzone are revolutionizing the landscape of lean manufacturing.

Discover how QAD Redzone’s Connected Workforce Solution elevates the traditional Andon system, optimizing manufacturing processes for the digital age. Book a demo today to explore the potential transformations for your operations.

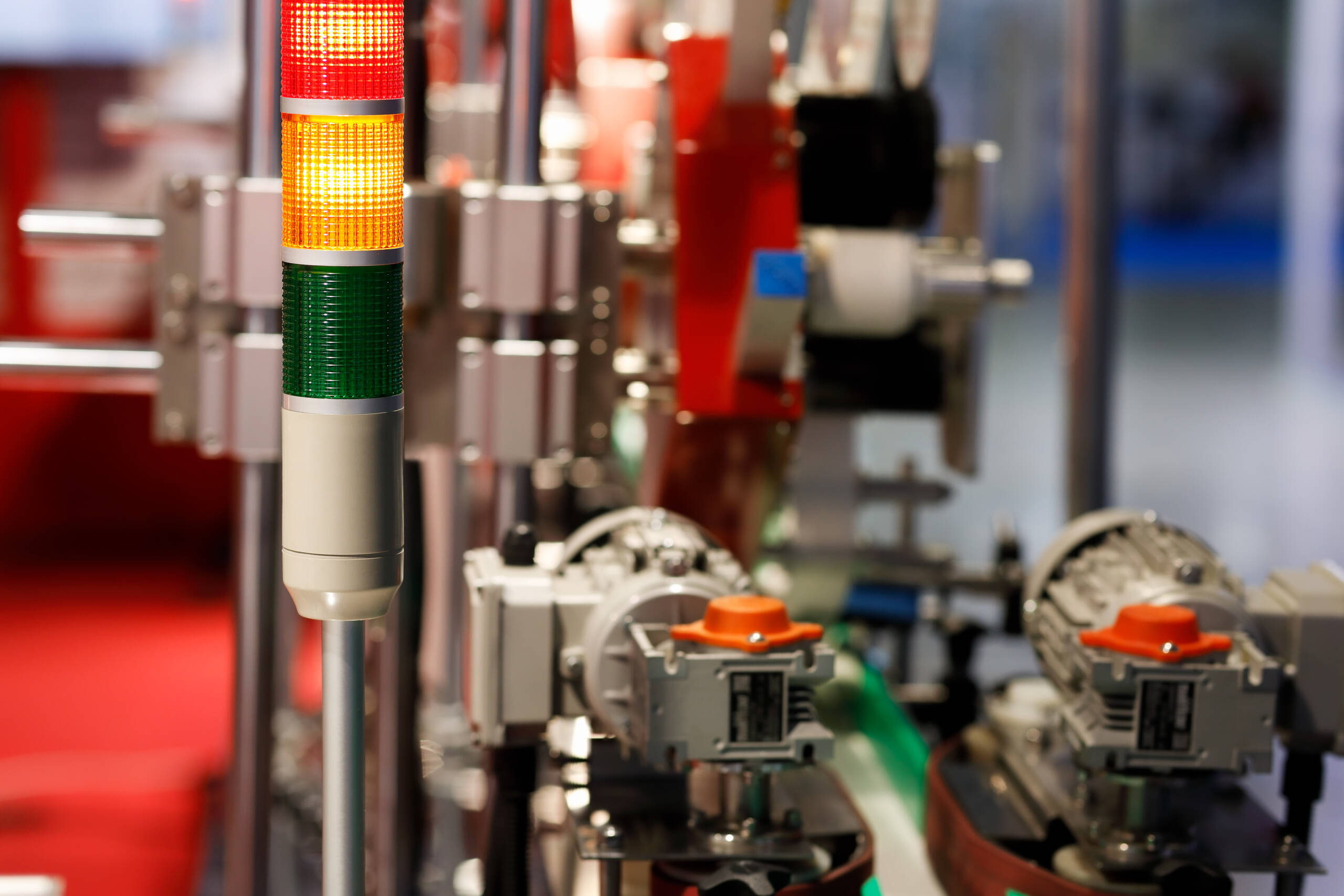

In the realm of lean manufacturing, Andon stands as a beacon of efficiency and communication. This visual signaling system (often similar to a red-yellow-green stoplight) is vital for real-time alerts regarding production issues, fostering an environment where problems are not just spotted swiftly but also addressed with speed, allowing for ongoing improvements in manufacturing workflows. Its role in fostering transparency and problem-solving is widely recognized across various industrial sectors, symbolizing a proactive approach to manufacturing challenges.

Andon’s roots stretch back to Japan, where it was cultivated within the Toyota Production System. As a testament to Toyota’s innovative spirit in the 20th century, Andon emerged as a pivotal communication tool, enabling workers to signal issues instantly to improve efficiency and maintain the rigorous pace of production while ensuring quality control. It encapsulates Toyota’s philosophy of ‘jidoka,’ highlighting issues at the moment they occur and stopping the process to fix them, thereby preventing the proliferation of defects and fostering a culture of continuous improvement.

Through its historical significance and practical benefits, Andon remains a cornerstone of lean manufacturing, embodying the principles of visibility, agility, and consistent excellence.

Andon systems operate through a combination of visual cues, color coding, and automation technology, facilitating efficient communication and problem-solving on the factory floor:

Integrating an Andon system into your manufacturing processes brings a suite of benefits:

By integrating QAD Redzone’s cutting-edge solutions, we can magnify these benefits, fostering an environment of continuous improvement and operational excellence.

QAD Redzone offers a modern solution that transcends traditional Andon systems. With QAD Redzone’s software, the Andon system becomes part of a comprehensive connected workforce platform utilizing social mobile applications on tablets and smartphones. This platform seamlessly integrates alerts, facilitates real-time collaboration, discussion, and documentation – ultimately creating a more connected and efficient manufacturing environment.

QAD Redzone’s software provides scalability, flexibility, and a digital environment for data analytics, documentation, and knowledge sharing. By aligning with lean manufacturing principles and promoting transparency, agile problem resolution, and the utilization of digital tools, Redzone revolutionizes the way manufacturing facilities operate.

QAD Redzone’s Connected Workforce solution offers a modern alternative to traditional Andon systems, enhancing the frontline alert mechanism with its innovative software. It provides not only immediate visual and audio alerts for production issues but also acts as a centralized digital hub, which greatly facilitates real-time collaboration, discussion, and documentation.

The seamless integration QAD Redzone offers ensures that teams can adapt workflows rapidly, promoting a culture of continuous improvement and empowering employees to engage proactively in problem-solving. This creates a more connected and dynamic workforce that is well-equipped to handle the demands of modern manufacturing.

Beyond addressing the immediate needs of the shop floor, QAD Redzone’s connected worker platform offers scalability and flexibility. It enriches the traditional Andon system with a comprehensive digital environment for data analytics, documentation, and knowledge sharing. This robust setup allows teams to deeply analyze trends, pinpoint root causes, and significantly boost overall productivity.

In aligning with the principles of lean manufacturing, QAD Redzone fosters an approach that emphasizes transparency, agile problem resolution, and the utilization of digital tools to refine workflows. The outcome is a more cohesive, efficient manufacturing environment that leverages the best of technology and process management for superior results. For further details, you can explore more on QAD Redzone’s product page.

1,000 Factories’ Productivity Data: The Largest Dataset of Its Kind ...

Contact us and let's begin empowering your frontline and growing your bottomline.