With frontline chat features, your manufacturing workers contribute their full potential. Redzone activates and elevates frontline teams; equipping them with new technology and skills to align with their company’s goals. Our connected worker platform leverages sophisticated communication tools for optimal manufacturing efficiency.

Effective communication is critical to keep the people, parts, and processes involved in manufacturing aligned and engaged every day. Redzone’s Connected Workforce Solution recognizes – and leverages – manufacturing as a team effort.

Aligned teams are optimized teams. Effective communication in real time creates a shared understanding of what is happening and what is prioritized; this ensures teams are aligned on daily goals and long-term strategies. When teams are aligned, their planned activities and discretionary efforts are more likely to contribute to the company’s goals.

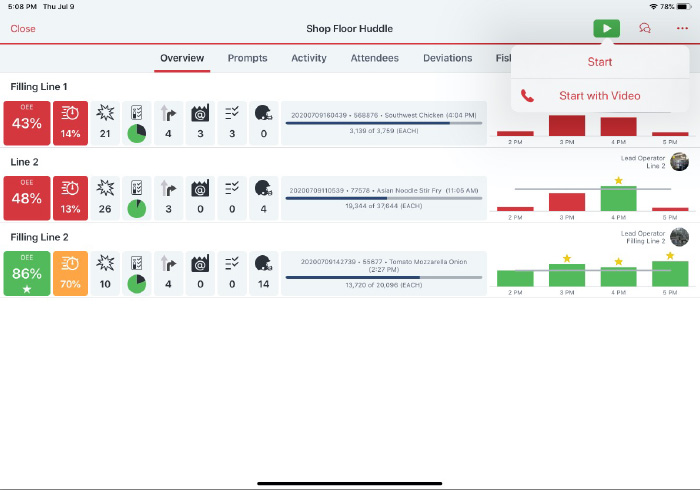

Meaningful, Timely, Relevant (MTR): these are what differentiate effective communication. Redzone’s Connected Workforce Solution ensures factories are communicating effectively to, from, and across the factory floor. Real-time dashboards communicate meaningful information on the status of each production line to all frontline team members at a glance. Communication and collaboration tools create such as chats and alerts connect relevant team members with events as they happen. Translation right in the app ensures that messages are shared with, and understood by, everyone for whom they are intended.

Unexpected changes happen in every plant. Meaningful, timely, relevant communication around change minimizes or eliminates non-productive minutes. Many factories depend on manual communication around what’s happening on the factory floor. Manual communications take effort. They are inherently delayed, lose meaning as they are relayed, and miss parties that are not physically available to receive the message.

Picture what can happen when a factory has a last-minute schedule change due to a missing packaging component and tries to communicate it manually. It might happen something like this: The shortage is unexpected and due to excessive rework on the line that has been happening all shift. The warehouse radios a forklift driver, who tells a line lead the next time they see them. That happens too late for a changeover to have happened at break and now it will be done mid-run, which means idle time for the employees on the line. The shortage is on packaging material, there is no way to finish the products on the belt, creating unexpected WIP to be transported to the warehouse as non-sellable goods. The line lead finds a supervisor to ask about what to run next. The supervisor decides to run the next item on the schedule. This new product requires maintenance to changeover the equipment. No one can raise maintenance on the radio. The lead goes to find a maintenance tech, and the only tech who knows the equipment is working on a planned changeover on another line and can’t do this unplanned changeover. No one remembered to communicate the changes to the scheduler and the next day the customer receives a shortage.

Communication in Redzone is meaningful, timely, and relevant. It is effective communication. A plant using Redzone to communicate will have a much different outcome in this example. The packaging shortage was due to excessive rework. Rework is being tracked in real time and is visible to all. The line lead sent a chat to the maintenance team and warehouse teams early in the shift. The line lead, scheduler, warehouse, and maintenance are seeing the trend as it happens. A three-minute huddle early in the shift allows them to proactively and collaboratively make a plan. The line is turned over to maintenance at break to service the packaging equipment and the rework is reduced. There is enough packaging material to finish the run, no changeover is required, and the order ships in full to the customer.

Empower manufacturing teams with a digital identity and voice—when they see something, they can say something. Solve problems effortlessly with social mobile communication, including chats, video calls, @mentions, line logs, push notifications, and more.

With Redzone, managers and leaders can efficiently broadcast plant-wide safety communication and important customer information through channels, alerts, and leader videos.

With Redzone, teams huddle around real-time AI-driven data to tackle the right problems, conduct root cause analyses, and take action. Interlocking forums connect frontline teams with plant leadership, ensuring barriers are removed for seamless problem-solving. Redzone’s manufacturing software saves time and boosts efficiency.

Rewarded behavior is repeated behavior and who doesn’t like breaking records!? Never miss a chance to recognize behaviors and results by sending high fives , good catches , and holding digital or in-person townhalls to elevate your frontlines and keep. your workforce motivated. Redzone’s manufacturing collaboration software makes it easy to identify your best performers and communicate your appreciation for boosted employee performance.