Learn How 1,500+ Factories Achieved Average 26% Productivity Gains in Just 90 Days Download Report

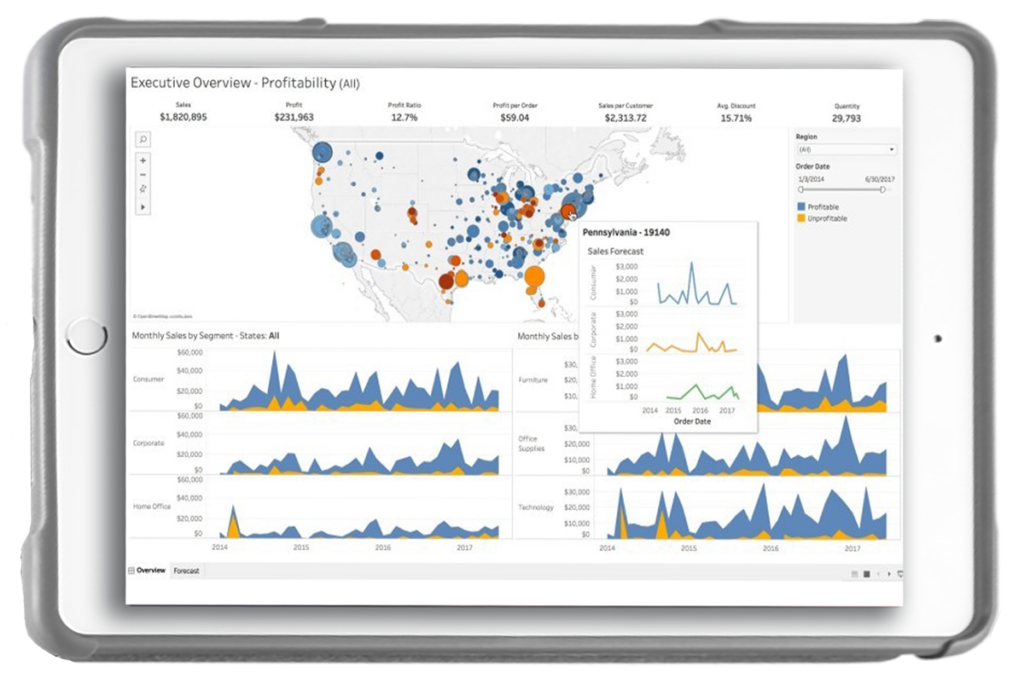

In a world where data was once the domain of a select few, Redzone’s manufacturing analytics platform empowers everyone in the factory to access and utilize valuable insights. This world-class analytics solution addresses reporting and visibility at every level of your organization. Offering pre-built reports tailored to each module ensures that you have the information you need at your fingertips – on any device! Once again, we’re setting the industry standard for manufacturing.

This is just the beginning. Our manufacturing analytics solution is designed to evolve and scale with your needs as your organization grows and expands.

Minimize downtime and maximize equipment performance with Redzone’s manufacturing analytics software. By leveraging real time manufacturing analytics, your team can monitor equipment health across the factory floor—spotting early warning signs before costly breakdowns occur.

With built-in anomaly detection, Redzone enables a shift from reactive to predictive maintenance strategies. Instead of relying on fixed schedules or post-failure fixes, your teams gain actionable alerts driven by sensor data and machine behavior patterns. This shift reduces unplanned outages, lowers maintenance costs, and improves overall productivity.

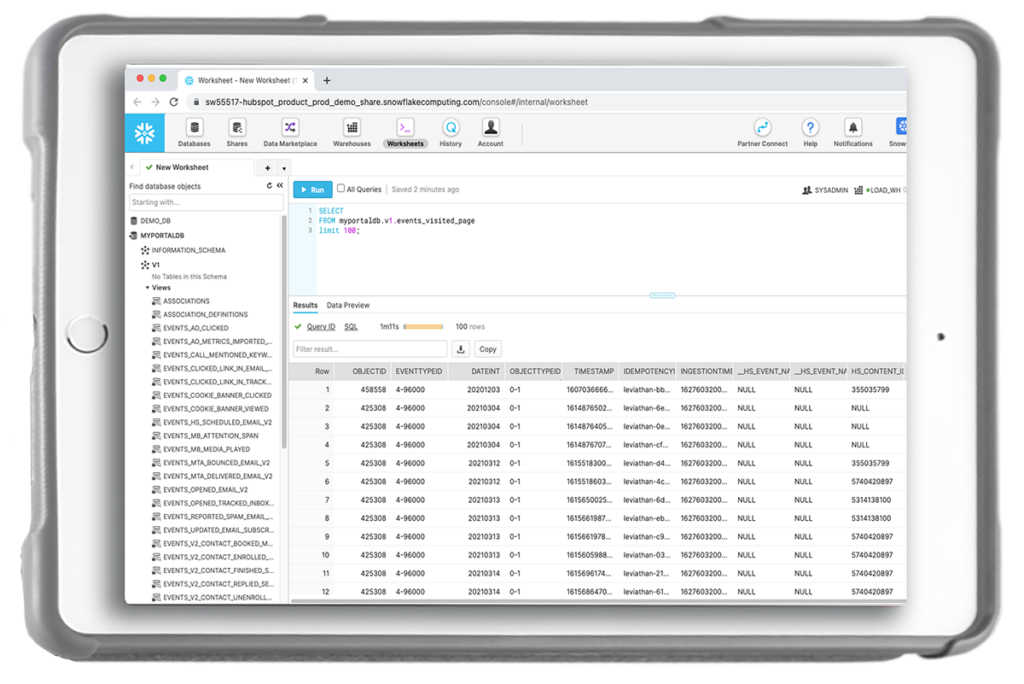

Our solution supports real time manufacturing data collection from machines, control systems, and IoT sensors. Combined with manufacturing visualization software, this empowers operators and engineers to understand equipment trends and take action before failure impacts production.

Minimize downtime and maximize equipment performance with Redzone’s manufacturing analytics. Every minute of nonproductive time is classified, monetized, and prioritized – automatically. Every member of maintenance and production teams can see instantly what the top drivers are for downtime on any line.

Redzone’s manufacturing analytics are available to everyone in the factory as soon as the Productivity module is live. Breakdown data and information about assets is captured. Descriptive information about equipment, like OEM, is part of the breakdown record from day 1. Reporting granularity even down to the serial number is available in Redzone analytics.

Enterprise customers understand patterns enterprise-wide with Redzone manufacturing analytics. This opens the door to understanding broader patterns that are having a negative financial and performance impact on the company but aren’t visible from within a single site. A single plant may see their lone asset from a specific OEM as a one-off problem child. However, when performance by OEM in addition to equipment type is readily available, and that site’s data is aggregated with other sites, an OEM whose equipment consistently underperforms is quickly identified. Imagine the leverage that having OEM-differentiated performance reports – with downtime monetized – provides maintenance and purchasing teams when working with OEMs.

The Redzone solution supports manufacturing data collection from machines, control systems, and IoT sensors. Combined with manufacturing visualization software, this empowers operators and engineers to understand equipment trends and take action before failure impacts production.

Modern manufacturing analytics software goes far beyond dashboards and reports. By collecting and analyzing real-time manufacturing data, teams gain immediate visibility into performance, downtime causes, and quality trends across production lines. This enables smarter decisions—whether you’re fine-tuning start up procedures, reducing rework, or scheduling preventive maintenance.

With real time manufacturing analytics, factories can proactively detect anomalies before equipment fails, reducing unplanned downtime and avoiding costly repairs. When combined with manufacturing visualization software, operators and engineers interact with data in intuitive, meaningful ways that drive efficiency and insight.

It’s not just about data collection—it’s about real time manufacturing data collection that’s at the center of your continuous improvement culture and empowers your entire operation.

Analytical manufacturing refers to the use of data science, statistics, and predictive algorithms to evaluate and improve production processes. Manufacturing analytics software captures and interprets vast amounts of data from equipment, quality systems, and sensors to optimize operations, detect inefficiencies, and increase yield.

Champion AI, Redzone’s agentic AI, creates meaning from these separate and extensive sources of data and provides preventive and prescriptive measures to maintenance and operations teams.

In a manufacturing setting, data analysts work closely with operations teams to track historical output, assess equipment performance, and forecast production trends. They often use real time manufacturing data collection tools to identify potential bottlenecks and apply manufacturing analytics software to improve process efficiency and product quality.

In a manufacturing setting, data analysts work closely with operations teams to track historical output, assess equipment performance, and forecast production trends. They often use real time manufacturing data collection tools to identify potential bottlenecks and apply manufacturing analytics software to improve process efficiency and product quality.

Redzone in-app real time dashboards and reporting portal are live day 1 and built with the goals of CI teams and data analysts in mind. Redzone shortens the time required to gather data to research complex issues from weeks to nearly instant.

The five core types of analytics often applied in manufacturing include:

1. Descriptive Analytics – What happened?

2. Diagnostic Analytics – Why did it happen?

3. Predictive Analytics – What might happen?

4. Prescriptive Analytics – What should we do?

5. Cognitive Analytics – What is likely to happen based on AI?

These analytics types help manufacturers make smarter, faster decisions using insights from real time manufacturing analytics platforms.

By using real time manufacturing monitoring, manufacturers can identify potential equipment issues before they lead to failures. This enables proactive maintenance and reduces costly unplanned downtime—ultimately driving productivity and extending asset life.

Contact us and let's begin empowering your frontline and growing your bottomline.