Découvrez les histoires inspirantes des travailleurs de première ligne : les grands noms de l’industrie manufacturière ! En savoir plus

November 30, 2022

The process of how goods are manufactured has significantly shifted since the dawn of the Industrial Revolution in the late 1700s. What was once done by hand, can now be accomplished in seconds thanks to machinery. This transformation from hands-on creation to machine work has had a major effect on product costs, bringing them down to a realistic level for the average consumer, effectively making manufacturing a societal force for good. But while it’s necessary to commend the advancements made over the years to machinery as a whole, the manufacturing industry would not be where it is today if it weren’t for the innovative technologies at the epicenter of the manufacturing industry.

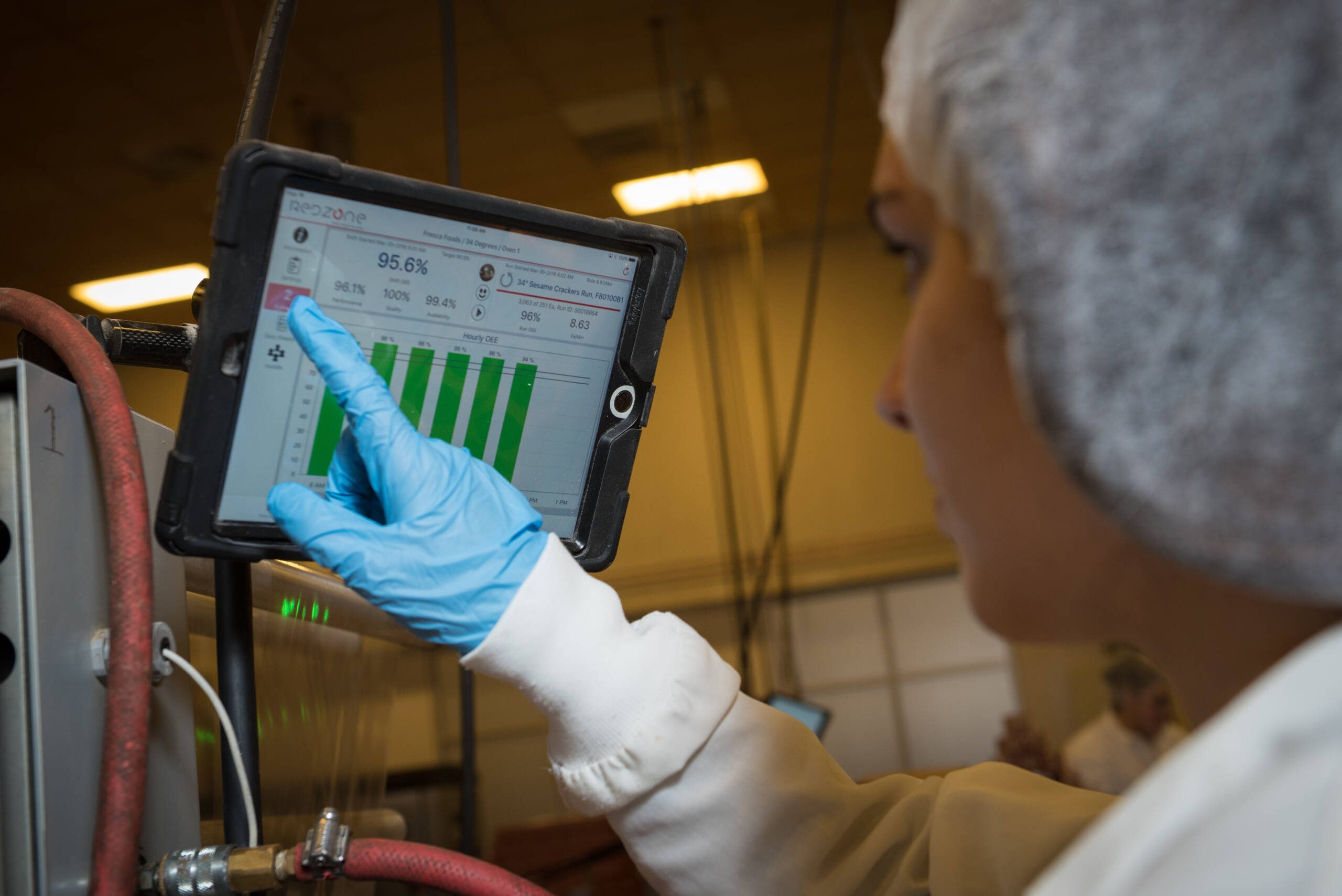

Over the last decade, this industry has been in a state of expeditious and integral transformation. On the demand end of the spectrum, manufacturers are up against consumers who want their products almost immediately and in high volumes. From an operational standpoint, manufacturers are faced with a cornucopia of technological offerings and tools to help radically improve demand challenges. Despite the importance of having the latest technological advancements incorporated within your machinery, it is even more valuable to integrate technology with your frontline workers and equip them with the right tools to help boost overall productivity and efficiency.

Here at Redzone, we pride ourselves on being the #1 connected workforce solution for manufacturers of all sizes – and thriving customers drive us every day. The explosion of mobile and social technologies, combined with lessons from behavioral performance coaching in sports, allowed us to create a solution that offers quick adoption on the frontlines with rapid results.

Our recent Frontline Worker Engagement Study dives deep into how our technology helps to boost employee engagement and increase productivity when empowered with technology. Overall, the plants from this study averaged a 74% increase across five engagement metrics.

What’s the business impact of this increased engagement? Reduced employee turnover and increased team productivity. A more productive workforce churns out more end product, which means fewer supply chain interruptions and, ultimately, more products on shelves and less inflation impacting all of us.

Additional Redzone data and customer stories are available here, as well as the Redzone savings calculator to determine real life savings for your factory.

Discover how plants authentically transformed their level of frontline engagement.

Contactez-nous et commençons à responsabiliser votre personnel de première ligne et à augmenter vos bénéfices.