Face à la pression croissante exercée par les pénuries de matériaux, aux exigences accrues des clients en matière de qualité des produits et aux préoccupations croissantes en matière de sécurité, la réduction des déchets et le respect des réglementations n’ont jamais été aussi cruciaux pour les fabricants et leurs travailleurs de première ligne.

Réduisez considérablement le gaspillage et les pertes en transformant votre programme d’assurance qualité à l’aide d’un logiciel de gestion de la qualité – en passant d’une approche réactive à une approche proactive, ce qui se traduit par une amélioration de la sécurité alimentaire et par des audits plus rapides et plus efficaces.

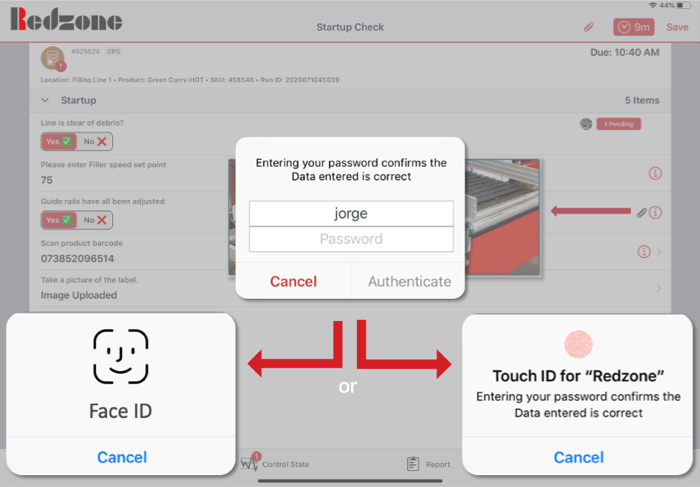

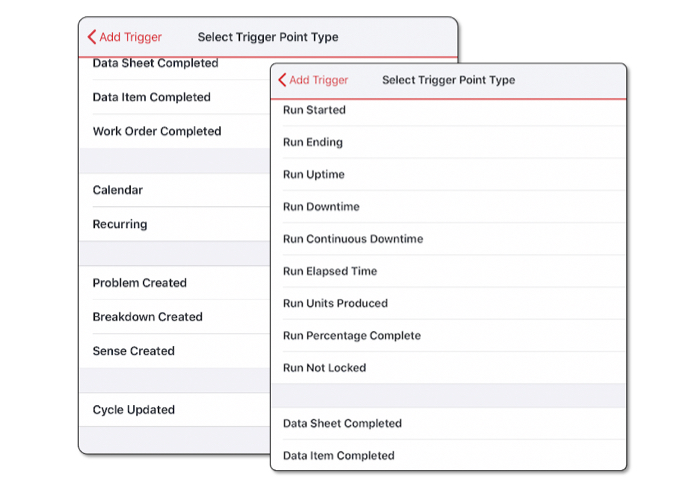

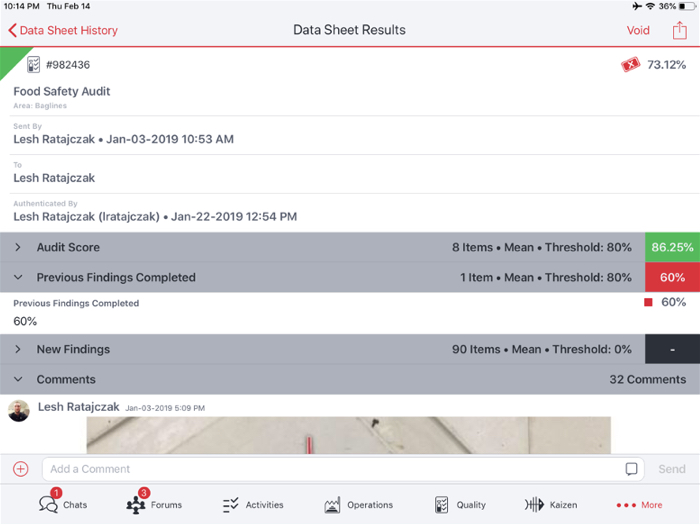

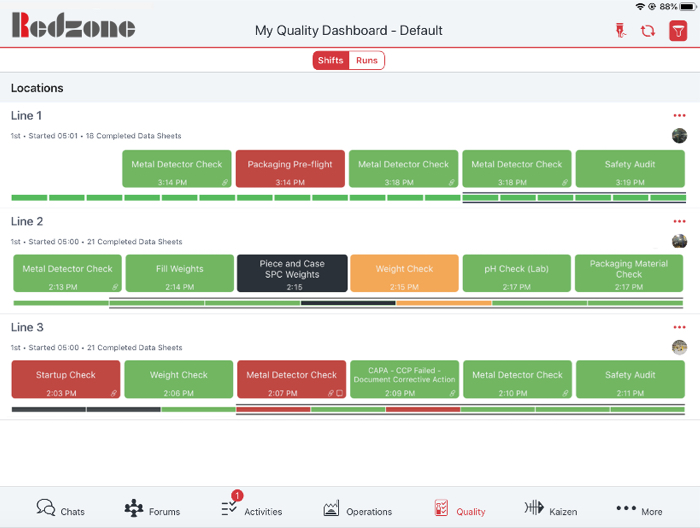

Notre logiciel de gestion de la qualité fournit des tableaux de bord à l’échelle de l’usine qui réduisent les tracas et les erreurs. Les déclencheurs et les alertes de manquement/échec/alerte permettent de ne négliger aucun contrôle. Protégez votre collecte de données en capturant des images de produits et en scannant des codes-barres pour une validation automatique, réduisant ainsi les déchets et les reprises. Chaque enregistrement est à portée de main, de sorte que les audits et les demandes de renseignements des clients ne prennent que quelques minutes, et non des jours.

Avec le logiciel de gestion de la qualité de Redzone, réduisez le gaspillage et la variabilité en ajustant les processus de manière proactive lorsque des conditions hors contrôle sont prévues. Calculez automatiquement les paramètres statistiques en temps réel tels que les limites de contrôle, Cp, Cpk et Cpp pour vous assurer que vos processus répondent aux spécifications du client.

Les usines Redzone inspectent ce qu’elles attendent en matière de sécurité et de conformité. Réalisez des audits avec une notation pondérée pour garantir le respect de la sécurité du personnel, de la sécurité alimentaire et des systèmes de gestion internes. Les listes de contrôle Redzone, configurables à l’infini, permettent aux usines de se passer de papier pour les inspections de sécurité, l’entretien ménager, les contrôles avant vol et toutes les tâches imaginables.